Mateusz Tokarz

R&D ENGINEER (STUDENT) | JUSTWAY PARTNER | CATIA V6 & FEM

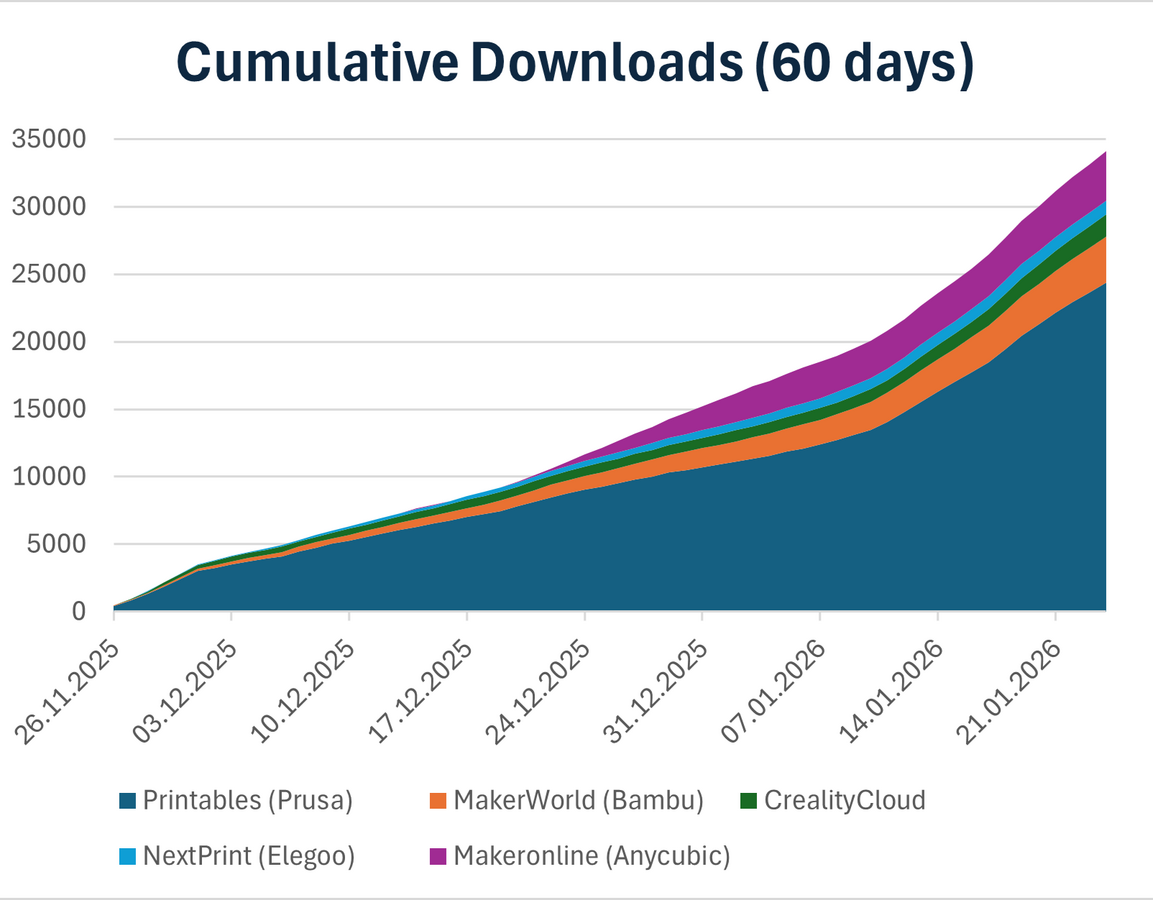

I bridge the gap between Theoretical Physics and Industrial R&D.I am not just a theorist – my functional designs gained 42,000+ verified users globally. This viral traction proves my strong grasp of Design for Manufacturing (DFM).Currently, as a Justway Technical Partner, I validate prototypes using CNC & Sheet Metal. I combine this with independent research (building a custom Impact Tester & FEM analysis). I specialize in CATIA V6 / SolidWorks and am available for immediate R&D challenges.

ENGINEERING PORTFOLIO

MARKET VALIDATION & INDUSTRIAL PROTOTYPING

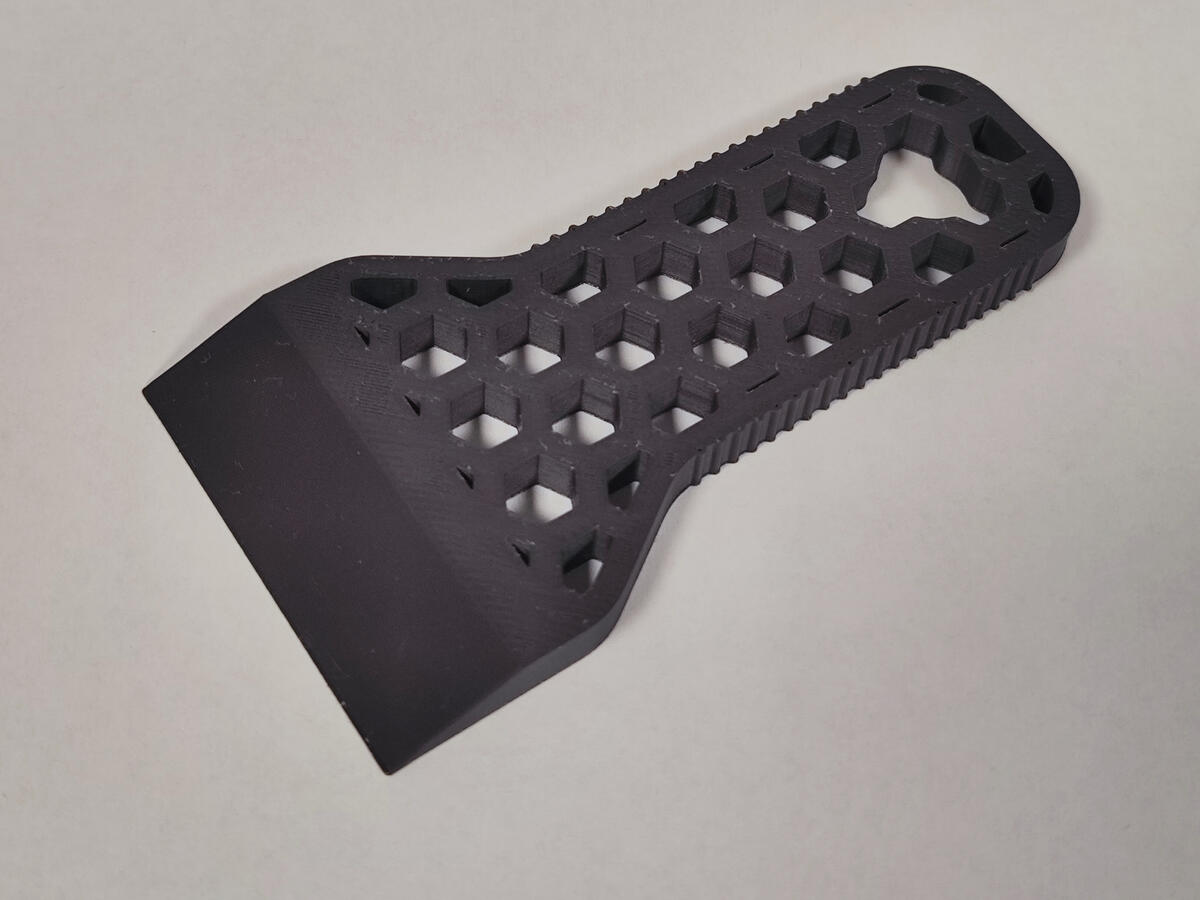

Design and market implementation of functional tools that gained 42,000+ verified users

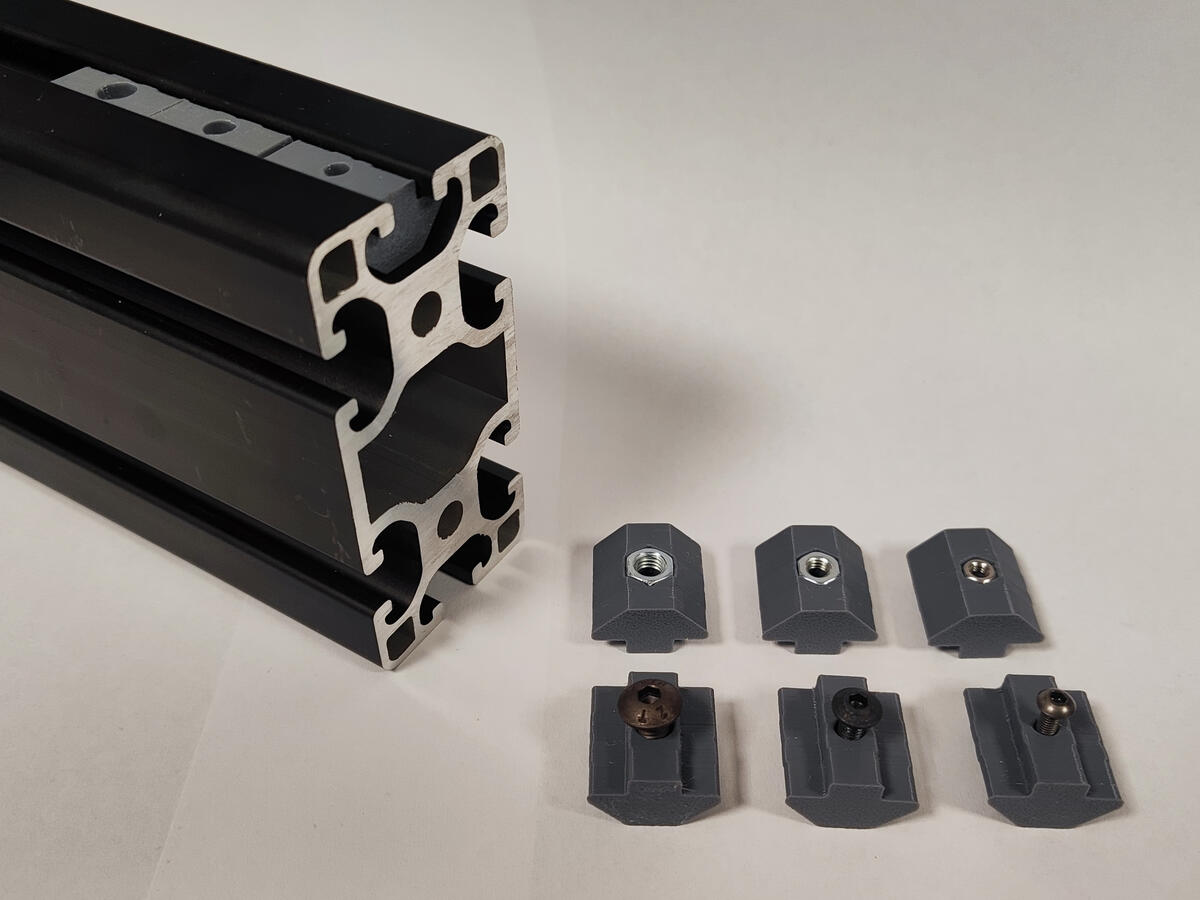

Justway Partnership: Collaborating with a global manufacturer to transition designs from 3D Printing to CNC Machining & Sheet Metal.

Goal: Validating DFM (Design for Manufacturing) standards for industrial-grade materials.

Software: CATIA V6 / SolidWorks.

INDEPENDENT RESEARCH (HARDWARE R&D)

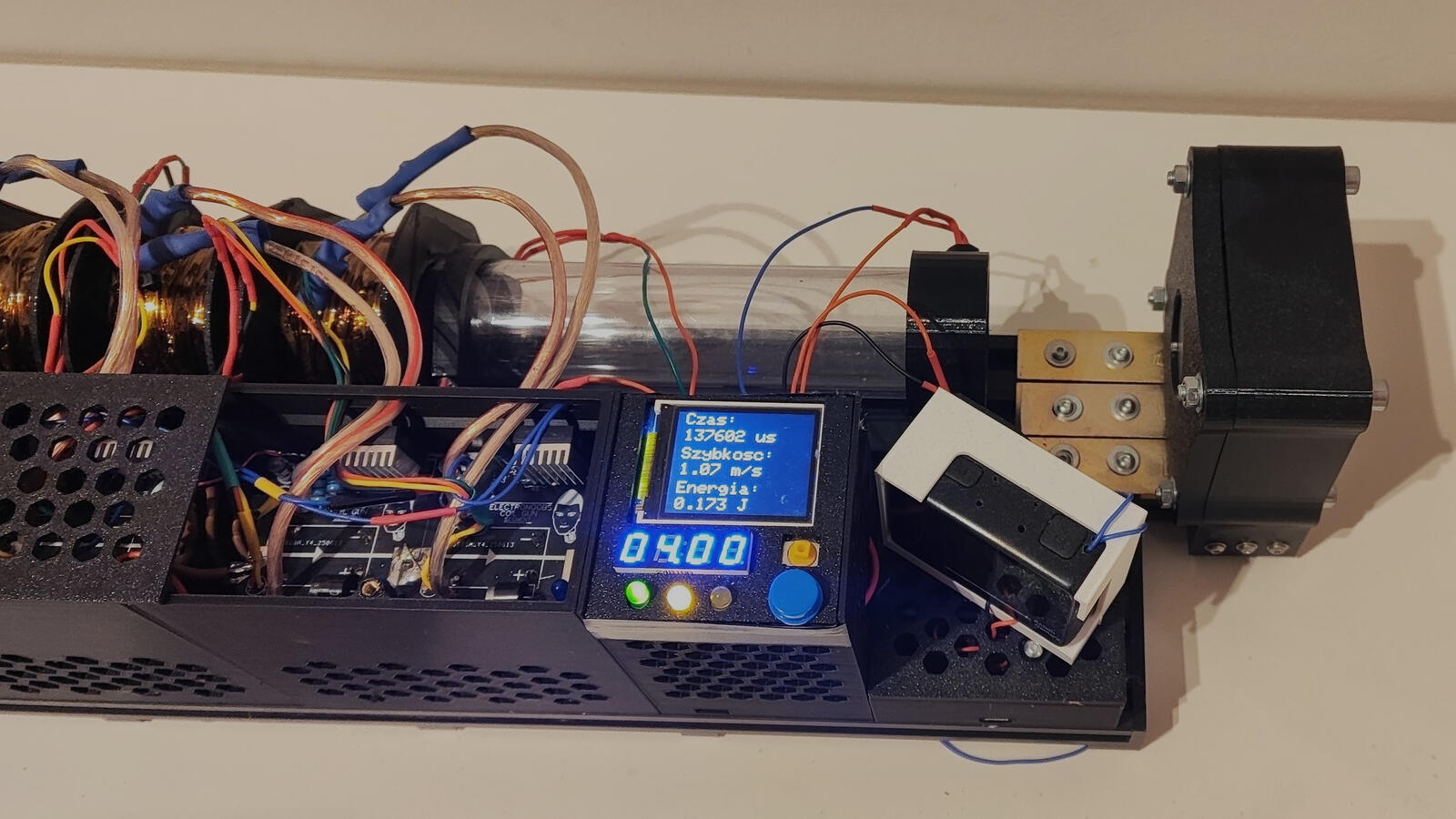

Construction of a custom automated testing rig from scratch (Independent Research – self-initiated project, not a standard thesis).

**System Integration: **Mechanical design, Electronics (ESP32), and Python data pipeline.

Validation: Bridging the gap between Virtual Simulation and Physical Reality.

Outcome: Correlating FEM results with experimental crash data.

ADVANCED CAD & FEA (SIMULATION)

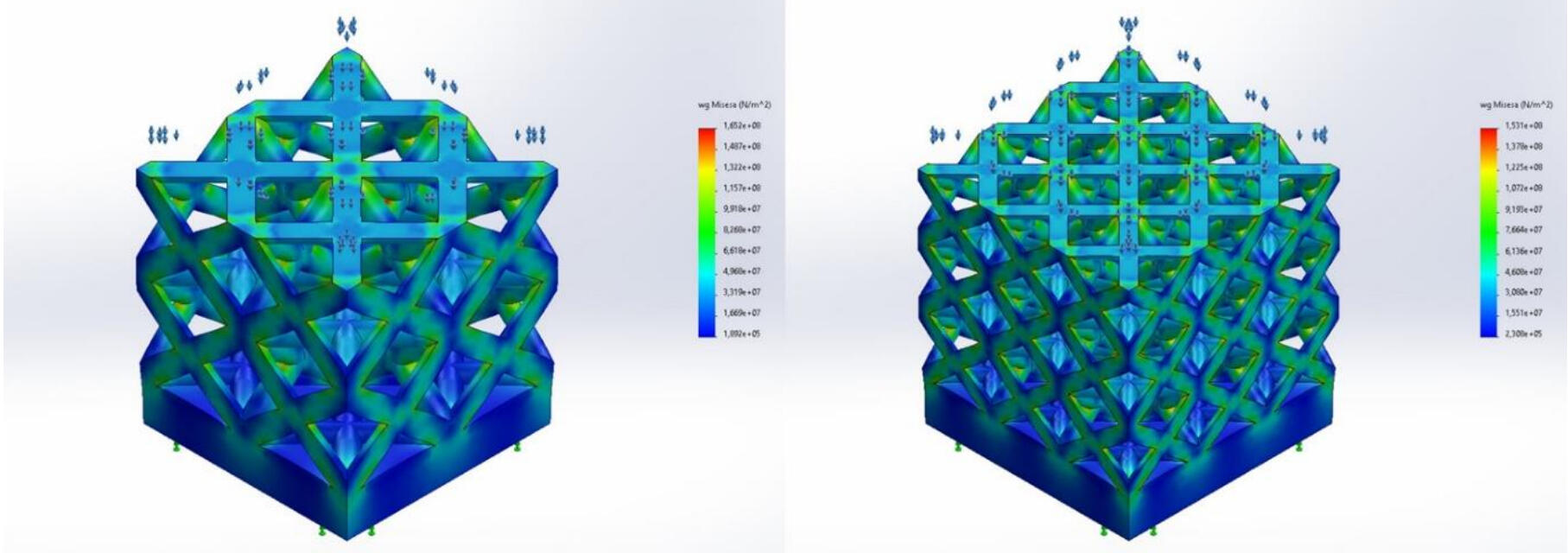

Structural analysis of lattice structures using SolidWorks Simulation (Static & Dynamic).

Methodology: Finite Element Analysis (FEA) of Von Mises stress distribution.

Application: Energy absorption analysis for crash-safety components.

TECHNICAL SKILLS

DESIGN & SIMULATION

CATIA V6 (3DExperience): Surface Design (GSD), Part Design, Assembly, Drafting.

SolidWorks: Parametric Modeling, Technical Documentation (2D), Rendering.

FEA / Simulation: Static & Dynamic Analysis (SolidWorks Simulation, SimScale).

PROTOTYPING & TESTING

3D Printing (FDM): Design for Manufacturing (DFM), rapid prototyping (Bambu Lab / Prusa).

Mechatronics: Custom test rig construction, Soldering, Microcontrollers (ESP32, Arduino).

Metrology: Dimensional measurement, Sensor calibration, Error analysis.

DATA SCIENCE & PHYSICS

Data Analysis: Python (Pandas, NumPy, Matplotlib), Technical data visualization.

Simulation Support: Surrogate Modeling (AI-assisted), Python scripting for automation, Process optimization.

Languages: English (Professional Working & Technical Proficiency).

COLLABORATION & AVAILABILITY

Availability:

July – September: Full-time availability (40h/week).

From October: Open to extending cooperation (Part-time / Flexible hours).

Location: Kraków, Poland

E-mail: [email protected]